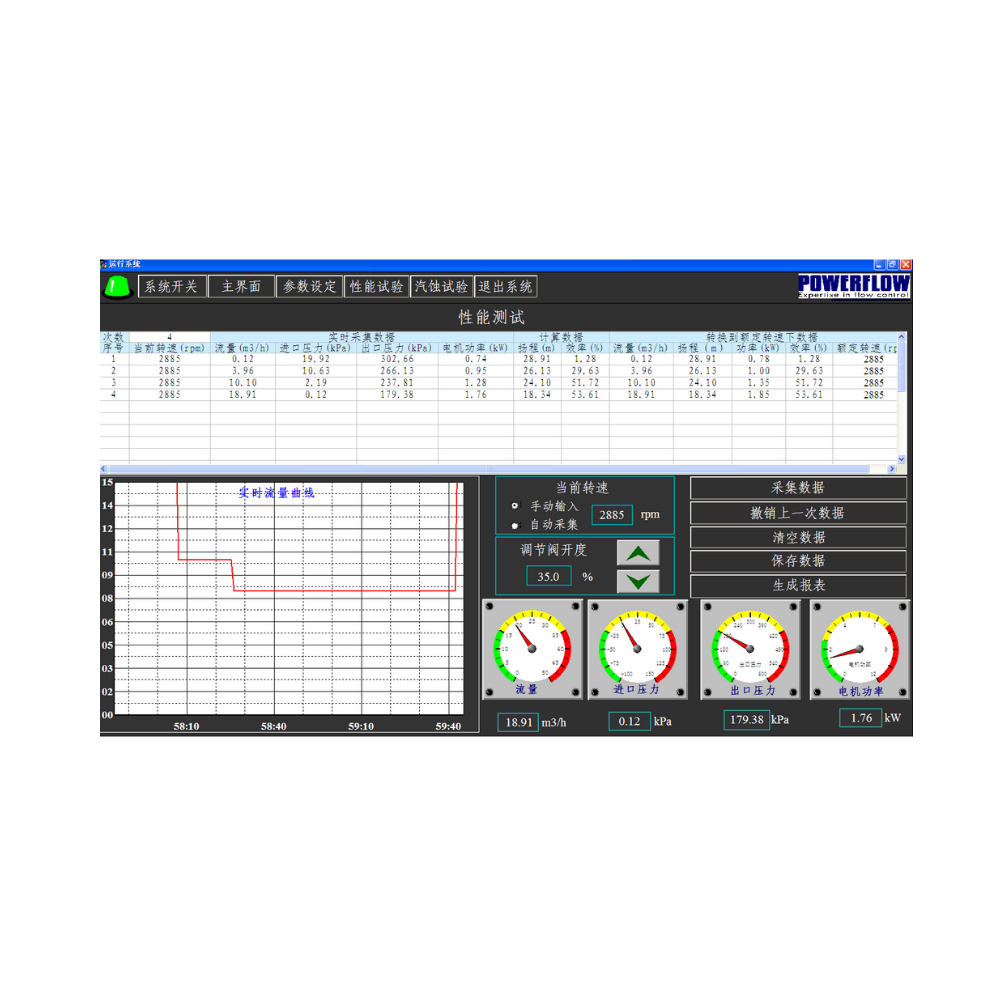

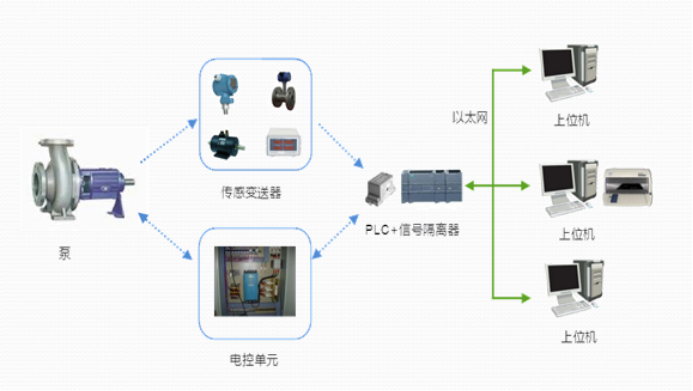

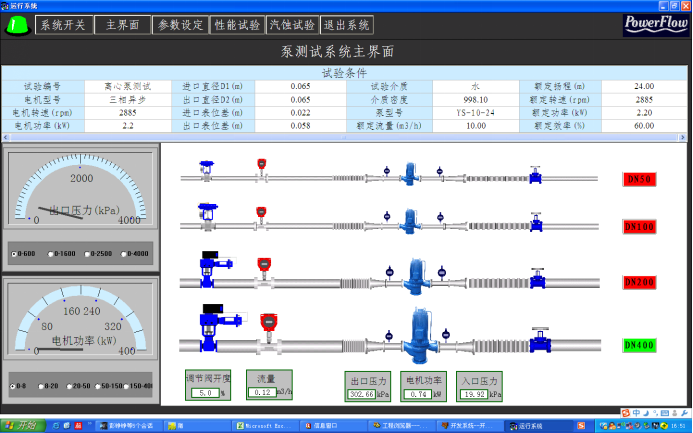

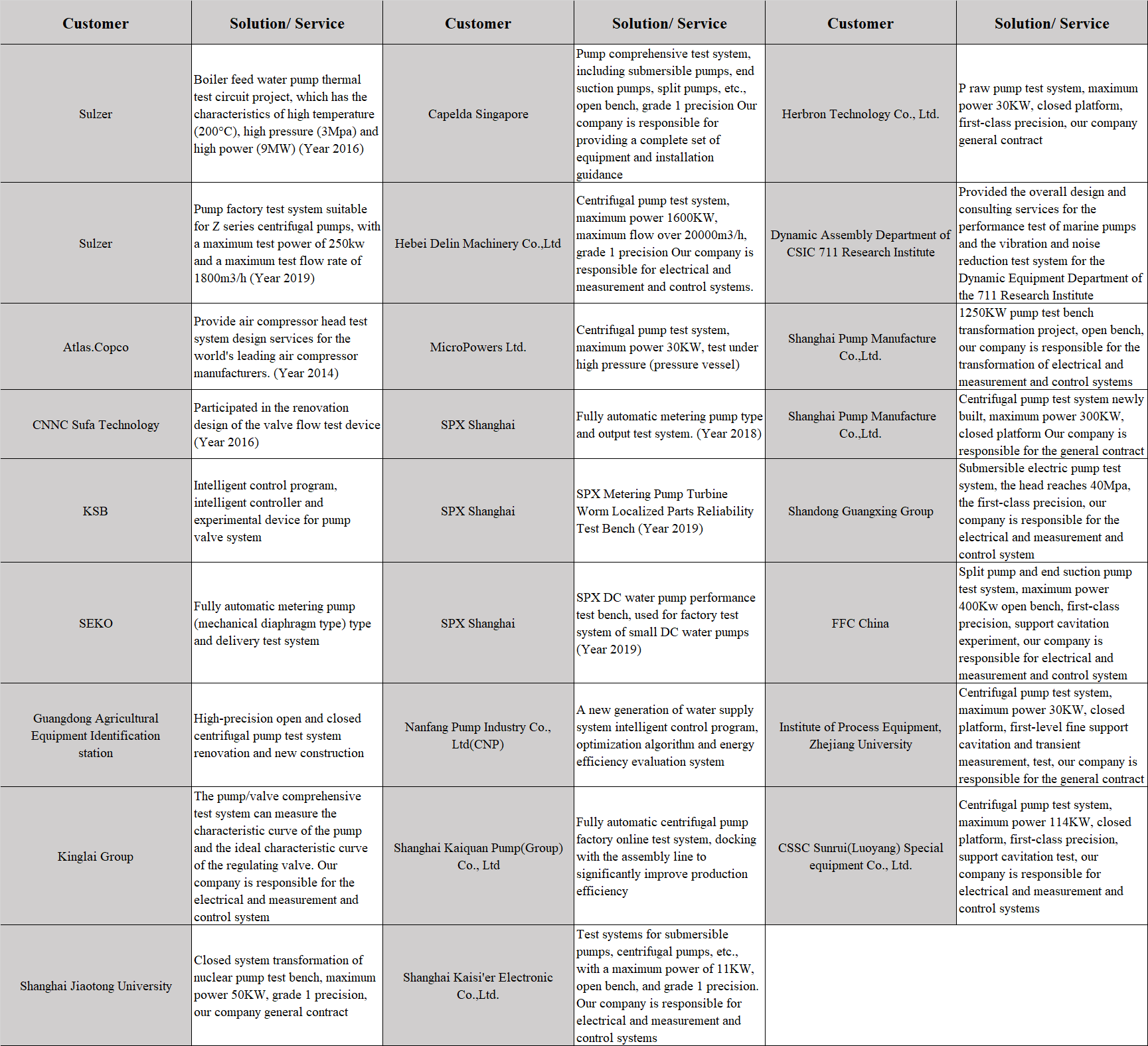

01 Brief introduction

With the increase of labor costs in the modern production process and the improvement of the quality requirements and testing standards of pump products, the original manual or semi-automatic testing methods can no longer meet the requirements. Powerful pump manufacturers have begun to use fully automatic pump testing system to improve their testing level and corporate image.

Compared with traditional manual testing, automatic testing not only reduces the workload of testers, improves testing efficiency, but also greatly improves testing accuracy. This test system can realize manual, semi-automatic and full-automatic testing of water pumps, realize automatic output of test reports, and test signals have good real-time performance and anti-interference ability.