01 Brief introduction

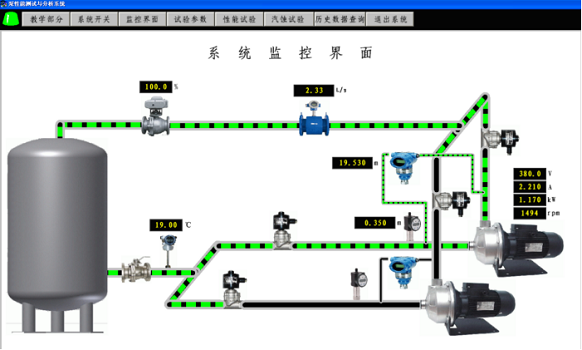

The comprehensive test system for centrifugal pumps for education (including basic version A and upgraded version B) is aimed at the education needs of colleges and universities for courses such as process machinery and fluid machinery, and is developed in strict accordance with GB/T 3216 pump test standards. As a small industrial-grade closed test system, it adopts advanced automatic control, data acquisition and analysis system, so that students can deepen the knowledge of centrifugal pump courses and improve their hands-on ability, and at the same time understand the test equipment, test methods, test instruments and automation in the industrial field. Control technology and broaden the knowledge of college students.